1 min read

Marking a Decade of the National Safety Stand-Down

Ladders. Scaffolding. Roofing. They’re prerequisites for most construction projects. With their help, crews build everything from homes to...

2 min read

Board of Certified Safety Professionals Oct 11, 2023 12:00:00 AM

According to the U.S. Center for Disease Control (CDC), an estimated 22 million workers – roughly a quarter of the workforce – are exposed to hazardous levels of noise on the job each year.

You may immediately think of industries dependent upon heavy machinery as the biggest culprits. Construction, with its jackhammers and drills, may come to mind. Or manufacturing, with its presses and grinders. Noise hazards, however, are not limited to those industries.

Power plants, warehouses, transportation centers, farms, call centers. These facilities and many more can subject workers to loud noises.

October is National Protect Your Hearing Month, offering a reminder to assess the noise-related risks in your workplace and to identify controls to protect workers.

As with all types of hazards, you should utilize the Hierarchy of Controls when planning your mitigation efforts. The list below offers a look at each type of control. As a reminder, the higher the control falls in the hierarchy, the more effective it is. Personal protective equipment (PPE), while vitally important, is always the last line of defense.

Simply put, remove the noise-producing object. This is the most effective option in the Hierarchy of Controls but typically the most difficult to implement. Noise is often produced by machinery that is vital to operations. If there is a viable way to work without it, do it. If that is simply not possible, move on down the Hierarchy.

Replace the noisy machine or tools with quieter versions. Newer models are often designed to operate more quietly. Changing the type of equipment can allow you to conduct the same work without subjecting workers to the same noise hazards.

If loud machinery is necessary to complete the work, take steps to isolate workers from the noise. You can do this by enclosing the noisy machine with a sound-absorbing barrier. The machine will function as normal, but workers will be separated from the noise.

If you cannot mitigate noise hazards with the controls above, you will want to incorporate policies and procedures to deal with them. These can include steps to assess the noise exposure of workers, rotate them to different jobs to keep them from constant exposure, conduct regular hearing tests of workers, and provide them with training on the proper use of PPE. These items often fall under the umbrella of a Hearing Conservation Program, which is required by OSHA for environments with average decibel readings of 85 dBA or higher over an 8-hour period.

Hearing protection for the worksite comes in several forms. Consider each of the following and check the Noise Reduction Rating (NRR) on the package to ensure the option meets your needs. Earplugs and earmuffs can be combined for additional protection, if needed. Remember, however, to calculate your total level of protection not by adding the NRRs of the two devices together but by adding five (5) dBA to the NRR of the higher-rated device.

Seriously contemplating all levels of the Hierarchy of Controls can go a long way in protecting the hearing of workers. Remember, hearing loss cannot be reversed, but it can be prevented. Take time this October to consider the noise hazards at your workplace and the ways in which you can address them.

1 min read

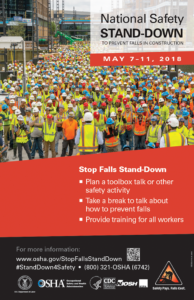

Ladders. Scaffolding. Roofing. They’re prerequisites for most construction projects. With their help, crews build everything from homes to...

2 min read

Noise is a physical hazard even though you can’t see it or touch it.

2 min read

After adding more than 30,000 jobs in January alone, the construction industry shows no signs of slowing down. With more workers comes more...